Lotiskorea Newsletter Vol. 31

|

|

|

📖 In this newest research, authors look at thermoelectric materials which can convert heat into electricity. Using the #FusionAX system, they were able to follow grain boundary changes at elevated temperatures!

💡Traditional high-temperature synthetic methods are normally hindered in synthetic methods, the ability to surpass crystal structure limitations and engineer defects. In this study, a new synthesis method is explored by the usage of powders and densification at lower temperatures.

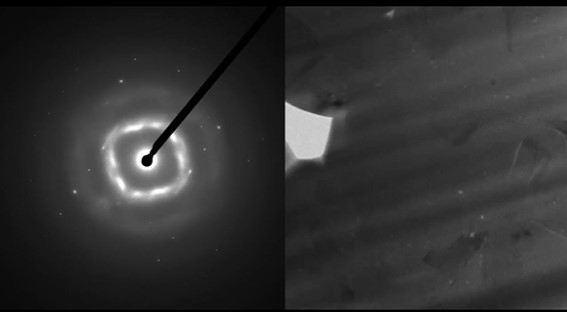

🔥This latest study focuses on Ag2Se, an n-type alternative to bismuth telluride. Through meticulous control of sintering temperature, a direct correlations between the concentration of Ag interstitials, grain boundaries, dislocations, and material microstructure was observed.

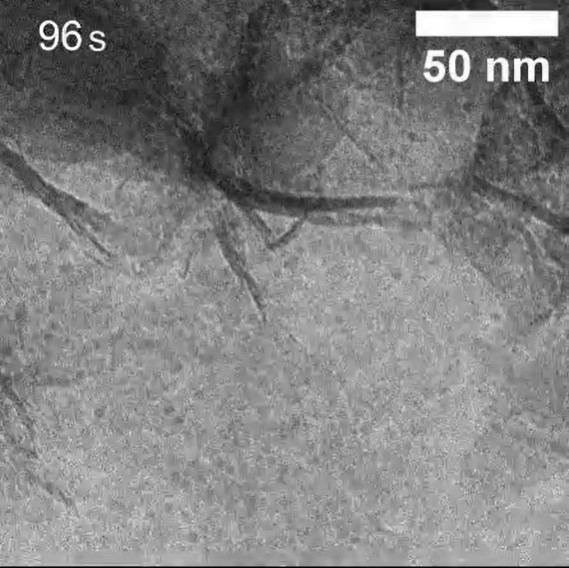

🔬The microstructrual changes were followed using in situ electron microscopy at elevated temperatures. Starting from focused ion beam (FIB) lamella preparation, the samples were heated up to 160 °C to observe grain orientation and coalescence.

These examples emphasize the transformative potential of innovative synthetic approaches in reshaping the landscape of thermoelectric materials and opening avenues for unprecedented advancements in the field.

The video shows both the microstructural transformation (right) and the diffraction pattern (left) during the transformation.

Want to read the entire study? Find it here:

https://hubs.li/Q02qMjYN0 |

|

|

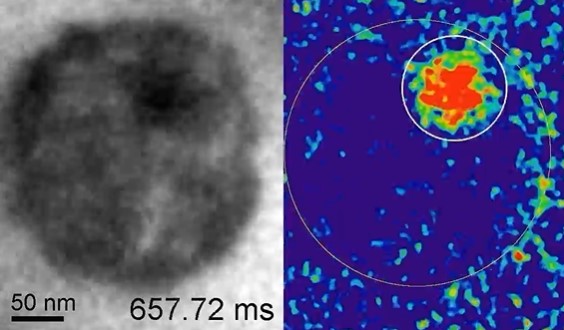

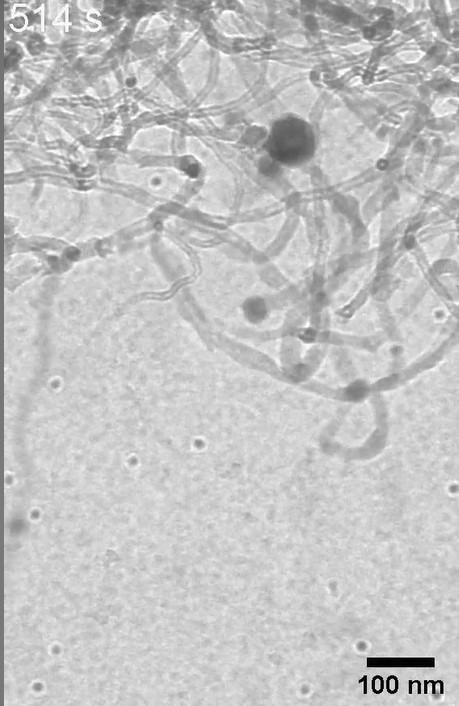

📖 In this newest publication in #NatureNanotechnology the authors are looking at magnetically powered nanomachines with a DNA clutch using the #PoseidonAX in situ liquid phase system! These systems exhibit intricate mechanisms, including a clutch system that allows temporary disengagement of moving parts from the engine—a feat that remains challenging to replicate in artificial nanomachines.

💧🔬 Using the power of liquid phase in situ electron microscopy, the authors were able to visualize the movements in a spherical rotary nanomotor equipped with a reversible clutch system, driven by precise molecular recognition of built-in DNA strands.

📈The nanomotor in this paper are designed to confine a magnetic engine particle within a minuscule nanospace. By eliminating the entropically driven irreversible disintegration during the disengagement process, this motor enables seamless exchange of microenvironmental inputs through nanopores.

💡 What's truly remarkable is the size and force capability of this nanomotor. At 200 nm in size, with a clutch-mediated force transmission powered by an embedded ferromagnetic nanocrystal, it delivers an impressive force of approximately 15.5 pN at 50 mT. This potency opens doors to exciting possibilities, including in vitro mechanical activation of vital receptors like Notch and integrin, showcasing its potential as nano-bio machinery.

Want to read the entire paper?

https://hubs.li/Q02qLnW10 |

|

|

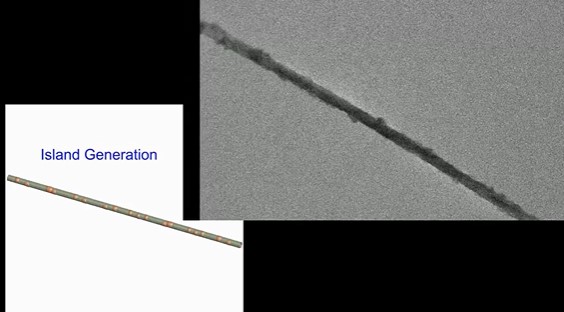

📖 This latest research, published in #NatureCommunications is looking at the transformation of one-dimensional (1D) materials in liquid using our #PoseidonAx system! Developping a versatile, and controlled synthetic method for these materials has long been a challenge, and can now be observed in real time and at the nanoscale.

💧The structural evolution of these 1D materials was followed using the #PoseidonAX system to study the read time growth of island formation. Combining the in situ microscopy experimentats and continuum phase-field simulations, a three-stage evolution process of regular segment alternations was observed.

🔍This synthesis strategy, complemented by straightforward chemical post-transformations, has lead to a wide array of 1D structures to be synthesed. These include 17 nanowire-nanowire and 8 nanowire-nanotube nanostructures, incorporating 13 different elements (g, Te, Cu, Pt, Pb, Cd, Sb, Se, Bi, Rh, Ir, Ru, Zn)!

💡 The synthesis-driven approach not only opens new avenues for investigating the reconstruction of ordering but also holds immense promise for unlocking the full potential of 1D-SHs in various applications.

Want to read the full study?

Find it here!

https://hubs.li/Q02tV6NX0 |

|

|

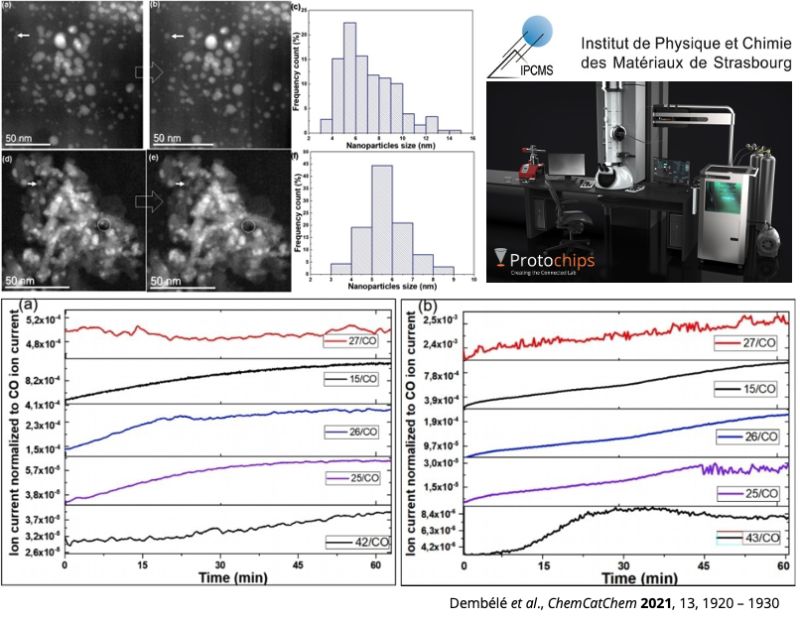

Are you interested in correlating your bulk catalyst activity to nanoscale behavior? Do you want to observe structural changes and correlate this to gas product formation?

With #AtmosphereAX, you can observe the structural and functional evolution of catalysts at the nanoscale in real time, under relevant gaseous conditions and up to 1 atm and 1000°C. Interesting, right? Here’s how this is uniquely possible with our #AtmosphereAX workflow solutions:

👩🔬 Preparation: User and TEM safety are prioritized with proactive pressure monitoring which shuts down the system if a leak occurs. To further support TEM safety and acquisition of reliable results, system cleaning/maintenance are streamlined, without the need for system disassembly.

🔬 Collection: Both heating and gas flow can cause sample instability and movement! With AXON Synchronicity, this is instantly corrected for, with live drift control and focus assist. No post-processing drift correction required! Additionally, all metadata is integrated into the software, for easy data review later.

🌬 Analysis: In addition to the structural evolution of catalysts, associating morphology with catalytic activity is also critical. With our uniquely designed ultra-quiet residual mass spectrometer (RGA), fast and highly sensitive gas detection is guaranteed, with no compromise to image resolution!

📈 Publishing: With AXON Studio, our free data review software, researchers can filter, plot, sort, easily identify trends, and create publish-ready videos and images in record time. No manual data correlation required!

Check out full blog post here: https://hubs.ly/Q02ylPPC0

Interested in scaling bulk catalysts experiments to the nanoscale, while maintaining the highest level of scientific rigor to share or publish relevant, reproducible, and reliable results? Click here to learn more: https://hubs.ly/Q02ylJ3T0

In the image you can observe the activity of two Fisher-Tropsch (FT) catalysts (Co/SiO2 top and Co/Al2O3 bottom). RGA measurements in combination with STEM imaging showed Co/SiO2 undergoing a higher degree of reduction, showing increased FT activity. For the full publication from Institut de Physique et de Chimie des Matériaux de Strasbourg - IPCMS, visit https://hubs.ly/Q02ylByV0 |

|

|

📖 Would you like to be able to observe a catalyst's synthesis behavior in water vapor? In this newest research by Savannah Turner, Nienke Visser, Remco Dalebout , Petra de Jongh and Krijn de Jong published in #Small, the researchers from #UtrechtUniversity looked at the role of water vapor on nickel based catalyst synthesis using our #AtmosphereAX!

🔬In this study, the influence of water vapor at the nanoscale during the reduction of a nickel phyllosilicate catalyst precursor under H2/Ar gas at 700°C was observed and compared with a dry synthesis at 500°C. The authors observed that water vapor not only suppresses and delays nucleation but also paradoxically accelerates particle growth.

☁️ As reduction progresses, water vapor plays a pivotal role in enhancing Ostwald ripening, leading to increased particle coalescence. This lead to the observed mechanism where water vapor facilitates the formation of mobile nickel hydroxide species, thereby promoting faster rates of particle growth during and after reduction.

💡 These findings deepen the understanding of catalyst synthesis dynamics, which can only be observed using nanoscale microscopy combined with gas, vapor and heating!

Find the full publication here:

https://hubs.li/Q02v82-d0 |

|

|

📖 This newest research published in #MaterialsAdvances looks at the thermal decomposition of methane into carbon nanofibers (CNF) using our #AtmosphereAX system! Suzan Schoemaker, Stefan Bismeijer, Tom Welling and Petra de Jongh from #UtrechtUniversity are visualizing the CNF formation behavior of supported bimetallic NiCu catalysts at the nanoscale.

💡This study started from NiCu catalysts and looked at the influence of the copper content on the carbon yield when forming CNF. It was shown that the optimal Cu concentration was ~30%, which maximized carbon yield. As the Cu content increased, this decreased the carbon solubility in the NiCu nanoparticles, influencing reaction kinetics and overall yield.

🔬Utilizing in situ electron microscopy small and intricate changes were observed in the metal nanoparticle morphology during carbon growth. This was done by first performing an in situ reduction step and then adding the methane gas at 1 bar and at 600°C.

📈It was also found that NiCu nanoparticles maintained larger, spherical shapes, fostering consistent carbon nanofiber (CNF) growth, while pure Ni nanoparticles exhibited variable shapes and interrupted CNF growth.

This research emphasizes the critical role of balancing carbon supply, transport, and nucleation in optimizing catalytic performance. It also shows the importance of integrating statistical measurements with microscopic insights to grasp overarching catalytic trends.

Want to read the entire research paper?

Find it here!

https://hubs.li/Q02v84hw0 |

|

|

문의

Email : hskim@lotiskorea.com

Tel : 010-2858-2798 |

|

|

|